Mini Inventory app for iPhone and iPad

Developer: Coding Mama

First release : 10 Dec 2012

App size: 1.71 Mb

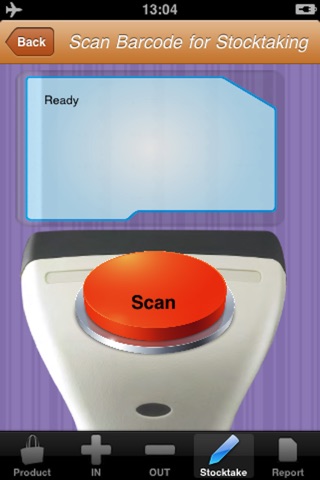

Manage mini inventory by barcode scanning, which applied to process of goods inward, goods outward and stocktaking.

For goods inward, it allows 2 workflows, either in +1 mode or +N mode. For +1 mode, barcode is scanned at item one by one continuously. For +N mode, a barcode is scanned followed by entering inward quantity.

Similarly for goods outward, it also has 2 workflows, either in -1 mode or in -N mode. For -1 mode, barcode is scanned at item one by one, while for -N mode, a barcode is scanned followed by entering outward quantity.

Periodically, if there is discrepancy between quantity in warehouse and database, stocktaking could be applied to synchronize the item quantity with the database.

There are various reports to analyze the inventory performance. For example, users could review the sorting of stock outward quantity of items between a date range, sorting of stock current quantity, etc.